- Check valves are also known as Non Return Valves

- Check valves are self-activating safety valves that permit gases and liquids to flow in only one direction, preventing process flow from reversing.

- They are classified as one-way directional valves.

- Fluid flow in the desired direction opens the valve, while backflow forces the valve closed.

- The mechanics of check valve operation are relatively simple.

- Most check valves contain a ball that sits freely above the seat, which has only one through-hole.

- The ball has a slightly larger diameter than that of the through-hole.

- When the pressure behind the seat exceeds that above the ball, liquid is allowed to flow through the valve; however, once the pressure above the ball exceeds the pressure below the seat, the ball returns to rest in the seat, forming a seal that prevents backflow.

- Check valves use a variety of technologies to allow and stop the flow of liquids and gases.

- Single-disc swing valves are designed with the closure element attached to the top of the cap.

- Double-disc or wafer check-valves consist of two half-circle disks hinged together that fold together upon positive flow and retract to a full-circle to close against reverse flow.

- Lift-check valves feature a guided disc.

- Spring-loaded devices can be mounted vertically or horizontally.

- Silent or center guide valves are similar to lift check valves, with a center guide extending from inlet to outlet ports.

- The valve stopper is spring and bushing actuated to keep the movement "quiet".

- Ball check valves use a free- floating or spring loaded ball resting in a seat ring as the closure element.

- Cone check valves use a free-floating or spring loaded cone resting in the seat ring as the closure element.

- Selecting check valves requires an analysis of performance specifications, materials of construction, connection types, and media.

- Performance specifications include valve size, pressure rating, media temperature, and valve flow coefficient.

- Most check valves are made of acetal polymers, aluminum, brass, bronze, cast iron, chlorinated polyvinyl chloride (CPC), ductile iron, copper, polyethylene (PE), polypropylene (PP), polytetrafluoroethylene (PTFE), polyvinyl chloride (PVC), polyvinylidene fluoride (PVDF), rubber, steel, or stainless steel.

- Connections for check valves can use threads, compression fittings, tube fittings, bolt flanges, clamp flanges, butt welds, socket welds, and union connections.

- In terms of media, check valves are rated for air, compressed air, water, hot water, cold water, potable water, salt water, wastewater, gasoline, diesel fuel, high-purity gas, liquefied petroleum gas (LPG), natural gas, sour gas, corrosive gas, abrasive material, acids, corrosive chemicals, adhesives, concrete, grout, coolants, hazardous materials, high-viscosity fluids, hydraulic fluids, liquid metal, lubricants, oil, powders, solids, rendering wastes, sludge, slurry, ash slurry, or steam.

- Check valves are available in Steel, Stainless Steel, Brass Materials & can be applicable for Low pressure Application, High pressure Application & for water.

CHECK VALVE OR NON RETURN VALVE

CHECK VALVE OR NON RETURN VALVE

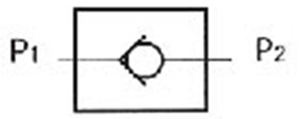

Designation & Symbol – CV

| Check Valves | Series | Sizes For Threads | Types of Threads Available | |

| Needle valves with Female Threads | 3000 | 6000 | 1/4" up to 2" | BSPP/BSPT/NPT/UNF |

| Needle valves with Male Threads | 3000 | 6000 | 1/4" up to 2" | BSPP/BSPT/NPT/UNF |

| Needle valves with Metric Tube Od | 3000 | 6000 | 6 mm upto 42 mm od | Metric Threads with Nut + Ferrule |

| Needle valves with UNF Tube Od | 3000 | 6000 | 1/4" od up to 2" od | UNF Threads with Nut + Ferrule |

| Check valves with Tube to Thread End | 3000 | 6000 | 6 mm upto 42 mm od | Metric to Bspp threads |

Materials

- Valve Body - Steel Phosphatised / Yellow chromatize / trivalent Zinc Blue Passivation

- Valve Body - STAINLESS STEEL -304 / 316

- Valve Spindle - Steel , Stainless Steel 304 / 316

- SEALING - WITH O RING -NBR - ( Viton - O ring - On Request at Extra Cost only)

- W.P. = Low Pressure = 200 bar & High Pressure up to 400 bar

- All other Parts are trivalent Zinc with Blue passivation

Non Return Valves - Tube to Tube End - For Hydraulic Applications

- Non Return valves tube to tube end are applicable for the systems where we have use Seamless tubes ( Metric / Inch Od / Inch NB types ) & to connect this tube end to this Non Return valves with Tube end & to Provide Nut & Ferrule Ring to get this tubes Grip with Non Return Valves Body.

- Non Return vales with Hydraulic tube end utilise in Paper Industry, Steel Plant manufacturer, Power Pack Manufacturer, Aircraft construction equipments, SPM, Process Machineries, Hydraulic Power Booster Units.

Non Return Valves with tube to tube end connection are available in below types & sizes

| Non Return Valves - Tube to Tube End | W.P.- BAR | Series | Sizes For Threads | Types of Threads Available |

| 6 MM to 15 MM OD | 250 | Light | 6 MM to 15 MM | Metric Threads both end |

| 18 MM to 22 MM OD | 160 | Light | 18 MM to 22 MM | Metric Threads both end |

| 28 MM to 42 MM OD | 100 | Light | 28 MM to 42 MM | Metric Threads both end |

| 6 MM to 12 MM OD | 630 | Heavy | 6 MM to 12 MM | Metric Threads both end |

| 14 MM to 25 MM OD | 400 | Heavy | 14 MM to 25 MM | Metric Threads both end |

| 30 MM to 38 MM OD | 250 | Heavy | 30 MM to 38 MM | Metric Threads both end |

Materials

- Valve Body - Steel Phosphatised / Yellow chromatize / trivalent Zinc Blue Passivation

- Valve Body - STAINLESS STEEL -304 / 316

- Valve Spindle - Steel, Stainless Steel 304 / 316

- SEALING - WITH O RING -NBR - ( Viton - O ring - On Request at Extra Cost only)

- W.P. = Low Pressure = 200 bar & High Pressure up to 400 bar

- All other Parts are trivalent Zinc with Blue passivation

Non Return Valves - Tube to Tube End - For Instrumentation Tube systems

- Non Return valves tube to tube end are applicable for the systems where we have use Seamless tubes ( Metric / Inch Od / Inch NB types ) & to connect this tube end to this Non Return valves with Tube end & to Provide Nut & Ferrule Ring to get this tubes Grip with Non Return Valves Body.

- Ball valves with Instrument Tube end utlise for Oil & gas Industry, Marine Application, PetroliumEquipments, Oil Refineries, Water Industry.

Ball Valves with tube to tube end connection are available in below types & sizes

| Non Return Valves - Tube to Tube End | W.P.- BAR | Series | Sizes For Threads | Types of Threads Available |

| 1/8" od up to 2" od Tube Size | 400 | Heavy | 1/8" up to 2" | UNF Threads both end |

| 6 mm up to 50 mm od Tube Size | 400 | Heavy | 6 mm up to 50.8 mm | UNF Threads both end |

Materials

- Valve Body - Steel Phosphatised / Yellow chromatize / trivalent Zinc Blue Passivation

- Valve Body - STAINLESS STEEL -304 / 316

- Valve Spindle - Steel , Stainless Steel 304 / 316

- SEALING - WITH O RING -NBR - ( Viton - O ring - On Request at Extra Cost only)

- W.P. = Low Pressure = 200 bar & High Pressure up to 400 bar

- All other Parts are trivalent Zinc with Blue passivation

Non Return Valves - Tube to Male End - For Hydraulic Applications

- Non Return valves tube to tube end are applicable for the systems where we have use Seamless tubes (Metric / Inch Od / Inch NB types) & to connect this tube end to this Non Return valves with Tube end & to Provide Nut & Ferrule Ring to get this tubes Grip with Non Return Valves Body.

- The other side of the Non Return Valves has Male / Female threads like BSPP / BSPT / NPT as per connection required to the end users.

- Non Return vales with Hydraulic tube end utilise in Paper Industry, Steel Plant manufacturer, Power Pack Manufacturer, Aircraft construction equipments, SPM, Process Machineries, Hydraulic Power Booster Units.

Non Return Valves with tube to Male Thread end connection are available in below types & sizes

| Non Return Valves - Tube to Male End | W.P.- BAR | Series | Sizes For Threads | Types of Threads Available |

| 6 MM to 15 MM OD | 250 | Light | 6 MM to 15 MM | Metric X Bsp Threads |

| 18 MM to 22 MM OD | 160 | Light | 18 MM to 22 MM | Metric X Bsp Threads |

| 28 MM to 42 MM OD | 100 | Light | 28 MM to 42 MM | Metric X Bsp Threads |

| 6 MM to 12 MM OD | 630 | Heavy | 6 MM to 12 MM | Metric X Bsp Threads |

| 14 MM to 25 MM OD | 400 | Heavy | 14 MM to 25 MM | Metric X Bsp Threads |

| 30 MM to 38 MM OD | 250 | Heavy | 30 MM to 38 MM | Metric X Bsp Threads |

Materials

- Valve Body - Steel Phosphatised / Yellow chromatize / trivalent Zinc Blue Passivation

- Valve Body - STAINLESS STEEL -304 / 316

- Valve Spindle - Steel , Stainless Steel 304 / 316

- SEALING - WITH O RING -NBR - ( Viton - O ring - On Request at Extra Cost only)

- W.P. = Low Pressure = 200 bar & High Pressure up to 400 bar

- All other Parts are trivalent Zinc with Blue passivation