- Flow control valves can be called as Throttle check valves.

- VE-LOCK® Manufactures valves which control & maintain the desire amount of flow as per application.

- Flow Control valves, Throttle valves can achieve the desire amount of flow of Fluid by rotating the spindle as per applications.

Flow Control Valves

Flow Control

Valves

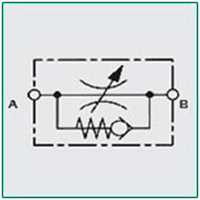

Designation & Symbol – DRV

Hydraulic Flow valves can be used as per required application like as below

- VE-LOCK® Flow Control Valves are designed as per DIN -ISO 1219, which can control the flow rate in oil hydraulic systems by means of an adjustable construction of the cross section.

- The Flow rate is dependent on pressure differential and Viscosity.

- VE-LOCK® Flow Control Valves with reverse flow check DRV allow the same fine flow adjustment.

- The flow control & shut off (check valve ) function in One direction only.

- Unrestricted flow in the reverse direction is via the build in check valve.

- Flow Control Valves with Reverse flow check consist essentially of a Valve body with build in valve seat, a hardened and Polished closing cone, a spring, the control spindle and the control knob.

- The closing cone is pressed on to the valve seat by the spring, thereby shutting off the port one to port two.

- Starting with the control spindle in the fully closed position when the flow is shut off, the flow rate in the flow direction increase according to the to the control know increased.

- The control knob with its coloured scale and scale rings permits accurate repetition of the settings.

- The size of the coloured triangle on the rings indicates the size of the flow area.

- An increase in the size of the coloured triangle corresponds to an increase in flow area.

- A set screw locks the setting.

- The closing cone opens when the pressure across port is higher then the cracking pressure of spring.

Advantage of Flow Control Valves

- Space saving inline mounting due to compact construction.

- A high level of safety is achieved through measured spindle safety mechanism.

- A set -screw locks the setting.

- Choice of Various sizes from 1/4 " up to 1 " ensures best possible adaptability to the system.

- Mounting Position is optional.

Applications of Flow Control Valves

- For controlling the speeds of loads

- For system-related damping in the Hydraulic Circuits.

- For pressure -dependent control of flow rate in general.

- To release pressure from accumulator systems.

- As an emergency drain for lowering a load.

Flow control valves are widely used in Hydraulic Power Pack Systems, Mobile Hydraulics, Elevating Platforms, Hydraulic Tippers, Contructionequipements.

Range

Fluid Temperature Range

- min. -20° C

- max. +80° C

Viscosity Range

- min. 2.8 mm2/s

- max. 800 mm2/s