- Valves are used in Hydraulic systems as very high pressure hydraulic fluid to perform various functions.

- Huge amounts of energy can be transferred over short distances much more efficiently with hydraulic systems than with electrical systems, especially when the desired motion is linear instead of rotational.

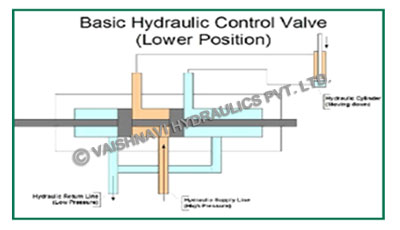

- A basic hydraulic system will have a pump, a pressure control valve, one or more control valves, one or more pistons or hydraulic motors that transfer the hydraulic power into motion and a return system that collects the low-pressure hydraulic fluid and feeds it back to the pump for re-use.

- This article focuses on the hydraulic control valve illustrated in below diagram.

VALVES

VALVES

Hydraulic High Pressure Valves

- VE-LOCK® Manufactures High Pressure Hydraulic Valves which is utilize to control Fluid Power & Motion in Piping Systems Hydraulic Valves are mainly in to various Types Like , Check valves , Ball Valves , Flow control valves , Needle valves & Manifold Valves.

- Hydraulic Valves can be use for High Working Pressure up to 10,000 psi ( 700 BAR).

- Hydraulic Valves are designed as per DIN /IS / SAE Standards as per its respective application in the Piping Systems.

Various Types of Hydraulic Valves - VE-LOCK ® Manufacturer

| Hydraulic Valves | Standards | W.P.- BAR | Sizes | Application for |

| Ball valves | DIN,IS,SAE | 700 | up to 2" | To Regulate High Flow, High Pressure & High Temp. Flow |

| Needle Valves | DIN,IS,SAE | 700 | up to 2" | To Regulate Accurate Flow & Pressure of Fluid at Low Rate also |

| Check Valves | DIN,IS,SAE | 700 | up to 2" | To Regulate Fluid Flow & Pressure in One direction only |

| Flow Control Valves | DIN,IS,SAE | 400 | up to 2" | To Regulate the needed Amount of Fluid Flow rate in One direction only |

| Throttle Valves | DIN,IS,SAE | 400 | up to 2" | To Regulate the needed Amount of Fluid Flow Rate in the system |

| Manifold Valves | DIN,IS,SAE | 700 | up to 1" | To Allow to regulate the flow & Pressure in Multiport type & in variety |